BACKGROUND

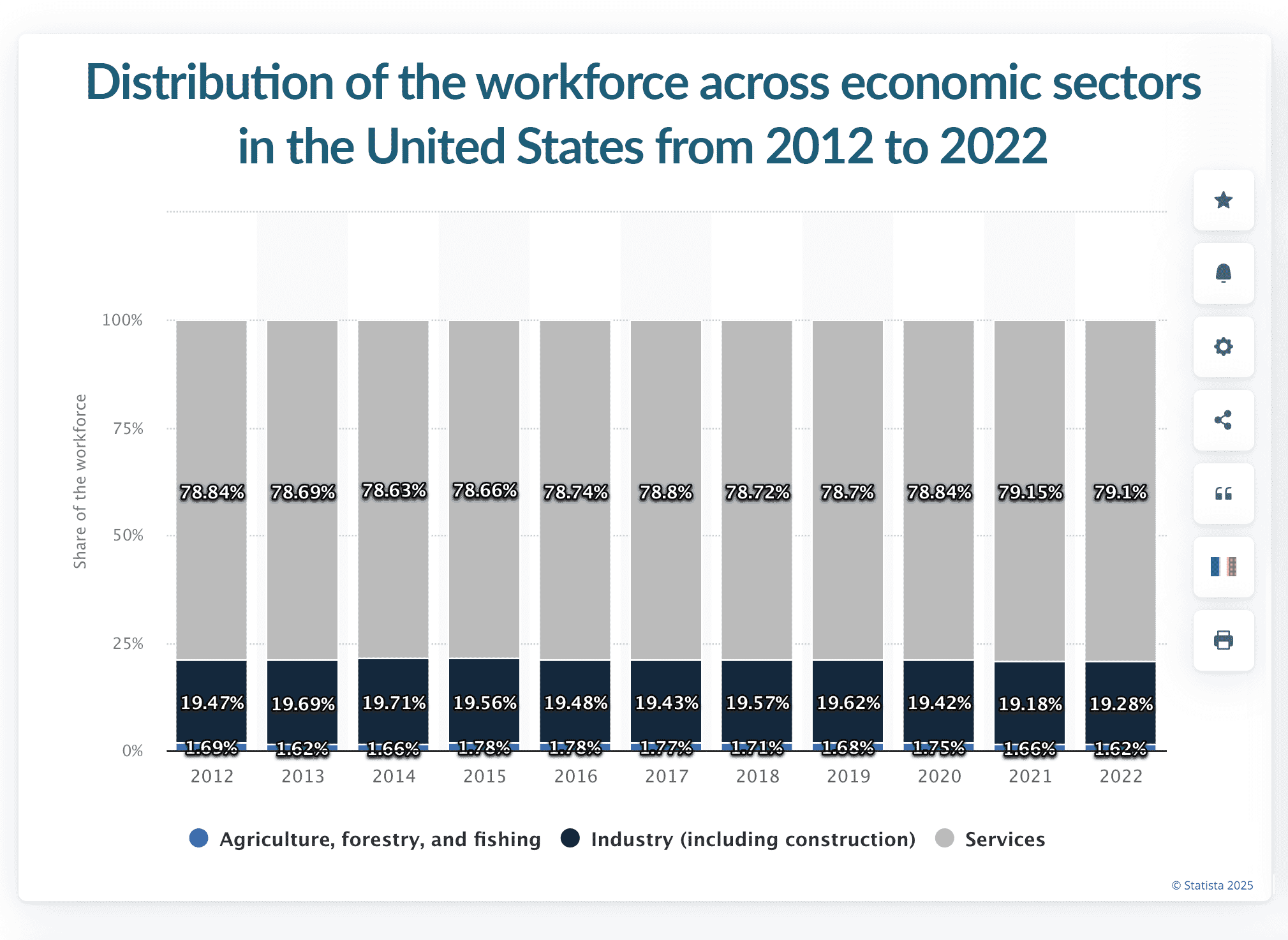

According to data from Statista, from 2012 to 2022 almost 20 percent of the US workforce is employed in the industrial sector, which includes mining, manufacturing, petrochemical plants and more. While there isn’t a specific percentage for “hazardous industrial worksites,” due to varying definitions and data collection methods, it’s estimated that a significant portion of industrial workplaces could be considered to have a high level of hazardous conditions depending on the criteria used to define “hazardous.”

GOING WIRELESS

We point this out in the context of enterprise connectivity in certain conditions where going wireless is preferable–on at least a few levels, to using Ethernet CAT-X and other cabling for industrial networks. With the high-bandwidth requirements brought on by Industry 4.0 style innovations–such as IIoT connectivity and increased automation (often robotic), mission-critical connectivity becomes of paramount importance for uninterrupted, 24/7 operations.

Wireless has always been used to fill in gaps in wireline infrastructure, or as a backup in case of a cable cut. But with there is now a case to be made to consider it as the primary connection medium, especially in harsh environments.

CHALLENGES

The environmental challenges in these industrial and manufacturing facilities include intense vibrations, extreme temperature fluctuations (E.g., -20° C to more than 40°-50° C), corrosive materials, and machinery in near-constant movement. For example, vibrations in moving machinery can cause equipment fatigue resulting in mechanical and electrical failures. Deployments like these often call for special ruggedized heavy-duty cabling, sometimes requiring metal-jacketed conduits.

In these environments, CAT-X cabling can become a single point of failure that can jeopardize a plant’s smooth 24/7 operations. CAT-X cabling can deliver Gigabit-speed connections, but may not be be feasible in certain locations of these facilities. And where it is deployed, it will have a shorter lifespan from the possibilities of cable cuts and caustic substances eating away its protective sheathing. Deploying cable in these areas could result in time-consuming and costly maintenance and replacement.

THE AIRVINE ADVANTAGE

The progress we have made over the last 18 months with the Airvine WaveTunnel and WaveCore product lines now offers management a cost-effective alternative to a wired network in mission-critical industrial and manufacturing settings.

The WaveTunnel has proven itself as a robust wireless backbone that can provide point-to-point-to-point connections in a daisy chain topology in a variety of scenarios. Operating in the 60 GHz band means the WaveTunnel is basically immune to interference from other sources of wireless transmission and has abundant spectrum available to provide multi-Gigabit speeds. This is why 60 GHz equipment is sometimes referred to as “wireless fiber”. Furthermore, while 60 GHz has traditionally operated on a strictly line-of-sight basis, Airvine is the first to achieve NLOS (non line-of-sight) connectivity in 60 GHz. This feature, combined with advanced beam steering, allows the WaveTunnel to go around corners. It can be used anywhere a cable can go.

PENETRATING CONCRETE WIRELESSLY

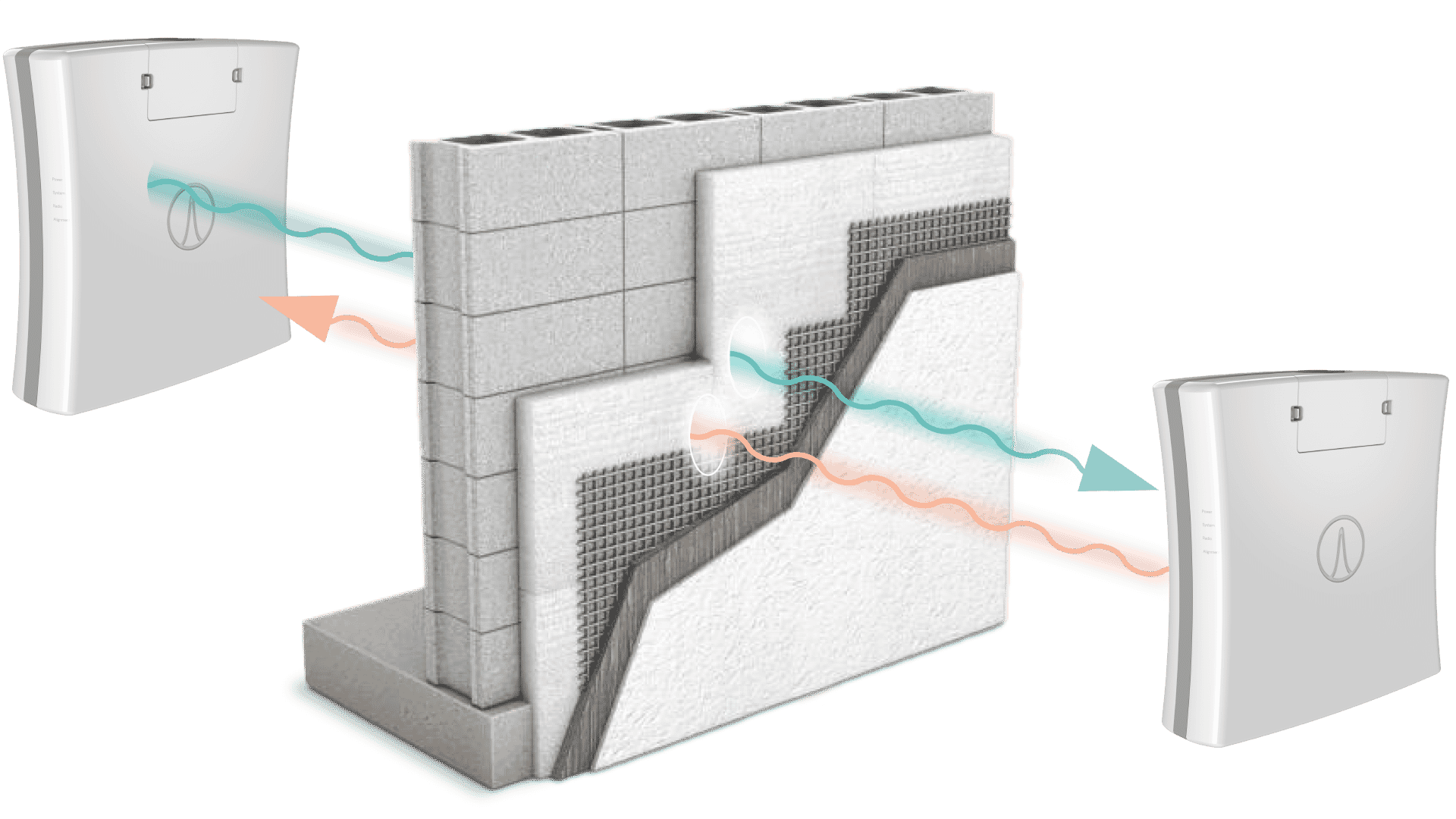

Excitement is growing over the demonstrated capabilities and potential of the new WaveCore system, launched in September 2024. This product was designed from the ground up to penetrate concrete, brick and similar materials in floors or walls that are 12 inches thick and more. Safety and structural support involves a lot of concrete infrastructure in factories and plants. The WaveCore eliminates expensive and time-consuming drilling, permitting and inspections required to run Ethernet networks through concrete barriers.

And the WaveCore is delivering. Recent deployments have achieved a 3Gbps connection through 8” of concrete in the middle of a 54-foot link, and a 4Gbps connection through a 12” concrete wall in a garage that was in the middle of a 6-foot link. The WaveCore can do the job in multi-story factories, too, as it can penetrate concrete floors that are usually a minimum of 4-5” thick and reinforced with rebar.

WAVECORE FIELD TESTING

During our extensive field testing we were able to demonstrate the performance in a variety of set ups including 12” concrete walls and across an entire stairwell. Click Here to see more results.

APPLICATIONS

So what kind of applications and benefits are we talking about? One top consideration pertains to worker safety: avoiding exposure to potentially dangerous chemicals and toxins when laying cable and during maintenance calls. The set-it-and-forget-it nature of the WaveTunnel and WaveCore creates an almost maintenance-free situation that will reduce downtime. In petroleum refineries, the wireless alternative presents a high-reliability option in flammable and corrosive zones.

And although not necessarily a harsh environment, food and beverage plants can benefit from Airvine wireless solutions for compliance with hygiene standards, since wireless is cleaner compared to cables.

BENEFITS

Key benefits from deploying a wireless solution from Airvine in harsh industrial settings:

- Cost Savings: there will be a reduced need for cable repairs and replacements and there is a lower labor cost for installation and maintenance

- Flexibility: Airvine offers a variety of options at first install and for network reconfiguration requirements to accommodate changes in a plant’s layout. It is suitable in both “brownfields” (as an overlay network or an extension to existing wired infrastructure) or “greenfields” (new construction) environments.

- Scalability: Airvine provides seamless integration with existing industrial systems and offers a “pay as you grow” model, as it is easy to add additional units as a plant expands

- Enhanced Reliability: referring to the “interference immunity” noted above, Airvine provides “five 9s” of reliability in harsh industrial deployments.

SUMMARY

Industrial networking requires high speed connectivity in environments that traditional cable was not designed to withstand. With caustic chemicals, moving machinery and the 24/7 nature of operation in these environments a wireless solution from Airvine offers a new, superior networking strategy.

Contact Us for detailed technical specs or to discuss your requirements with a local sales rep.