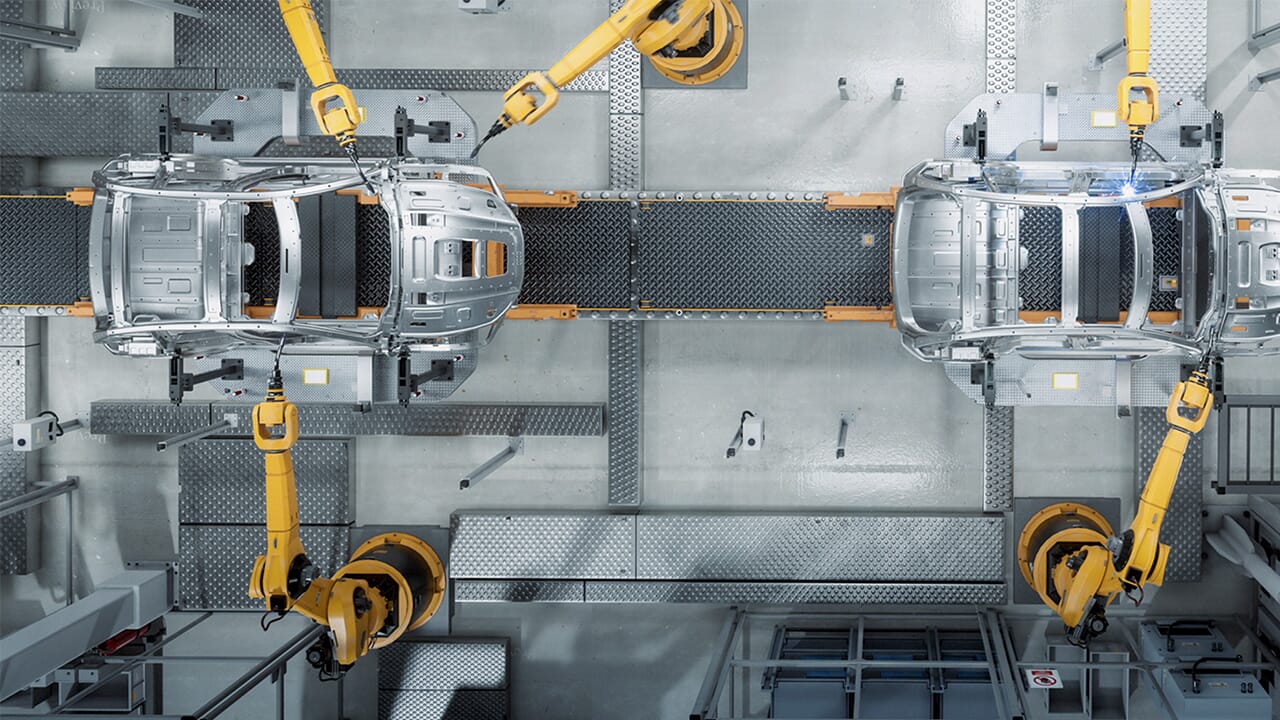

Running Ethernet cables in a factory environment presents several challenges due to the unique characteristics and requirements of factory settings. Yet the Industrial 4.0 wave sweeping around the world demands faster and more prevalent ethernet connectivity. Revolutionizing factory connectivity brings many benefits. These include IIoT, remote monitoring, asset tracking, worker safety, and productivity, as well as automation and robotics.

Challenges Presented by Ethernet Cabling – and the Solution

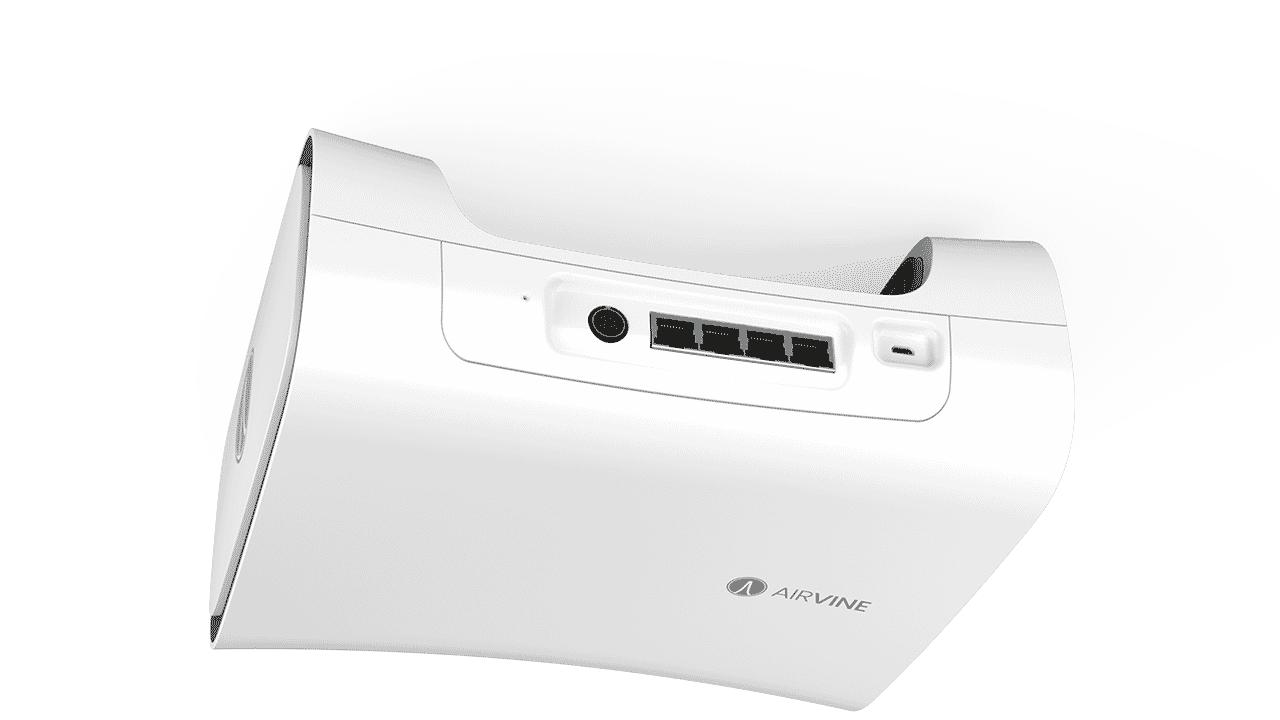

Meeting the growing demand for more bandwidth in challenging environments requires a more effective approach. The Airvine WaveTunnel system addresses these challenges as a point-to-point-to-point backbone solution that operates wirelessly in the 60GHz frequency band. Furthermore, it offers a range of up to 100 meters and a throughput of up to 2Gbps. The WaveTunnel’s unique signal penetrates walls and steers 90 degrees around corners, simplifying deployment.

Revolutionizing Factory Connectivity with the WaveTunnel

| Challenge | The Problem | The Solution |

Harsh Environment |

Extreme temperatures, dust, moisture, chemicals, vibrations, and other harsh operating conditions in factories can damage Ethernet cables. To maintain reliable performance, factories require more expensive, ruggedized industrial-grade Ethernet cables. | Keep the network off the floor. The WT nodes are mounted on the ceilings or high up on walls. No special cables are required, and in these locations, the units are spared from much of the environmental effects. |

Physical Obstacles |

Complex layouts in factories, featuring machinery, equipment, piping, and structural elements, can hinder Ethernet cable installation. Consequently, routing Ethernet cables through tight spaces, around obstacles, or in hard-to-reach areas requires careful planning and installation expertise. | Get rid of the cables all together.

Mounted on the ceilings, the WT avoids all the equipment placement and routing issues involved when running a wire on the floor, or even worse under the floor. |

Distance Limitations |

The Ethernet standard used (e.g., copper or fiber) limits Ethernet cable length. This limitation necessitates the use of additional networking equipment such as switches or repeaters in large factories to extend its range. | If longer distances are needed, the WT can be deployed point-to-point-to-point for a reach of 200m. Additionally, adding a fourth node can extend the reach to 300m and so on – with no signal degradation. |

Flexibility and Scalability |

Installing Ethernet cables to allow for future flexibility and scalability can be challenging. It requires careful planning, cable management, and documentation to ensure easy maintenance and future modifications. | Keep it simple.

The WT network is wireless, making it easy to relocate the WT node as the factory configuration changes or expand the floor space by simply moving, mounting, and plugging in the node. |

Safety and Regulations |

Complying with safety regulations, such as electrical codes, fire codes, and safety guidelines, may necessitate additional precautions, certifications, or specialized cabling solutions, adding complexity and challenges to the installation process. | Bypass the specialized cabling solutions.

With a wireless CAT5 backbone powered by WT, complicated cabling regulations are a thing of the past. |

Maintenance and Troubleshooting |

In factory environments, maintaining and troubleshooting Ethernet cables require specialized tools and expertise. This minimizes disruptions to production processes caused by cable breaks, connector failures, or signal disruptions. | Implement a wireless network.

There are no cable breaks to decipher and no switches to cool and a WT network can be designed to provide 99.99% availability. |

In the future, fast and reliable connectivity will be crucial for the development of factories, and traditional wired approaches present challenges as outlined earlier. Revolutionizing factory connectivity, while Ethernet cabling will remain a component of factory networks, incorporating WaveTunnel nodes offers increased flexibility and faster upgrades. If you’re interested in learning more, feel free to contact Airvine.